+91 8758687144

High and uniform surface temperature, energy effciency and good runnability are the three key requirements commonly placed on dryer cylinders. Having delivered more than 1000 dryer cylinders, RRK is uniquely qualified to pro-vide products that meet all of these demands. Accurate dimensioning, high-quality cast iron materials and precision manufacturing ensure the excellent runnability of all RRK cylinders. RRK can supply appropriate dryer cylinders for any machine size and speed.

All cast iron dryer cylinders are designed and manu-factured to the speci cations of applicable pressure vessel standards (ASME, PED, AD-2000 and JIS), and the cast iron materials, dimensioning criteria and man-ufacturing methods employed are based on the national requirements of each country of destination. e standard cylinder diameters are 1,830 mm (72") and 1,500 mm (60"). e thickness of the shell wall can be optimized on a case by case basis to ensure maximal heating effciency.

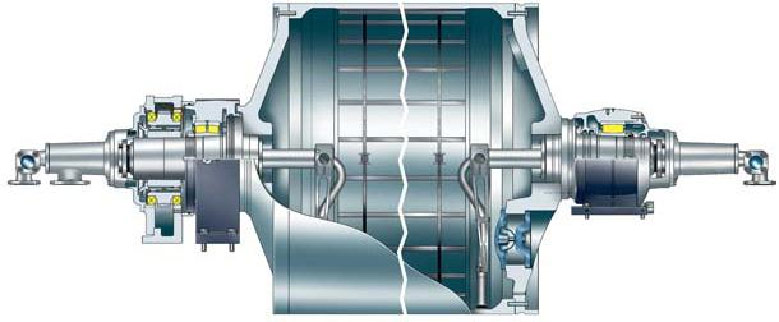

Dryer cylinders can be supplied up to 11 bar (160 PSI) of working pressure. e shell to head connection is sealed using the most suitable sealing method for each pressure class, all used sealing materials are asbestos-free. A toroidal roller bearing capable of han- dling the axial movement caused by the thermal expansion of the cylinder is used on the tending side and a spherical roller bearing on the drive side.

Cylinder journals are equipped with stainless steel insulating sleeves that form an insulating air pocket between the journal bore and the hot steam or conden-sate ow. is arrangement re-duces the temperature of the journal and slows down temperature changes during the warm-up period. e resulting reduction in the thermal expansion and operating temperature of journals helps to extend the useful life of bearings.

Design of RRK dryer cylinders. Condensate removal can be arranged from one or both ends depending on cylinder size.

DriBars are U-pro led low-carbon steel bars that are xed to the inside surface of the cylinder shell using special mounting straps designed to permit thermal expansion. e length of the bars is optimized to provide the most even surface temperature. DriBars improve the transfer of heat through the shell by breaking up the lm of condensate forming inside the cylinder shell. DriBars boost the energy effciency of dryer cylinders and also improve sheet moisture pro-les through more uniform dryer surface tempera-tures.

Dryer cylinders can be equipped with RRK's DriCombi or DriCompact steam and condensate units for safe and trouble-free steam supply and leakproof condensate removal. Condensate is removed through a stationary siphon. Its sturdy design ensures effcient and vibration-free operation under all running condi-tions. Cylinders can be supplied with a direct drive sha or an integrated DRG-gear unit. ey can also be provided with a free-wheeling rope pulley. e pulley is made of lightweight aluminum and its special design makes it changeable without removing the dryer cylin-der from the machine.

e cleanliness of the rst dryer cylinders can present a challenge at the dryer section and at the pre-dryer (a er sizing or coating) with certain paper and board grades. RRK can offer a variety of cylinder covers for these positions. RRK's DryOnyx H release coating has been developed speci cally for these demanding applications. DryOnyx H consists of wear and corro-sion resistant hard carbides that are topped with RRK's patented Onyx polymer for excellent sheet release. Chromium plating is available as another option. RRK also supplies doctor blades that are designed and tested speci cally for each cover mate-rial.

| Cover | Hardness | Material |

| Dry Onyx H | 800-1300 HV | Hard carbide + polymer |