RRK Vacuum Control Piping Systems

Vacuum control piping systems must be correctly designed with respect to separators, droplegs and headers. The header needs to be sized to supply sufficient vacuum to each low and high-vacuum area. Also, the droplegs in each section need to be sized to provide sufficient area to evacuate the water removed by each table structure. The following recommendations are based on industry and internal company standards and are provided below for general guidelines.

High Vacuum Applications

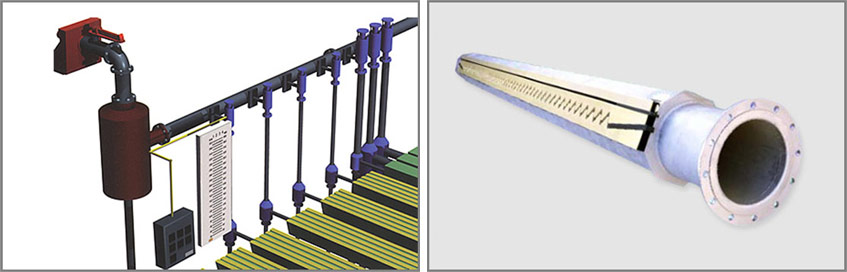

Typical Layout for Vacuum Piping and Control

- Header: Size for air velocity less than 3000 fpm (915 mpm)

- Standpipe: Sized as function of the V-1000 valve size

- 3" valve = 4" standpipe

- 4" and 6" valve = 8" standpipe

- 8" valve = 12" standpipe

- Separator: Size for air velocity less than 500 fps (152 mps)

- Box outlet and separator inlet

- Size for air velocity less than 3000 fps (915 mps) and water velocity less than 3fps (0.90 mps)

- Dropleg: Size for water velocity less than 3 fps (0.90 mps)

Low Vacuum Applications

Typical Layout for Vacuum Piping and Control

- Header: Size for air velocity less than 3000 fpm (915 mpm)

- Standpipe: Sized as function of the V-1000 valve size

- 3" valve = 4" standpipe

- 4" and 6" valve = 8" standpipe

- 8" valve = 12" standpipe

- Separator Inlet

- 4" for fabric width less than 260 inches (6600 mm)

- 6" for fabric width greater than 260 inches (6600 mm)

- Size for air velocity less than 500 fps (152 mps)

- V 1000 sizing : Use sizing curves if in doubt

- Wire width less than 200" (5080 mm) and air flow less than 300 cfm: 3" V-1000

- Wire width greater than 200" (5080 mm) and air flow greater than 300 cfm: 4" V-1000

- If DP high and air flow greater than 500 cfm: 6" V-1000

Vacuum Header

Vacuum header sizing is based on the principle of flow velocity through a pipe.

Vacuum Separator

As with the vacuum header, the vacuum separators are sized for specific air velocities through a pipe.